MethodicConfigurator

Motor Test Sub-application Architecture

Status Legend

- ✅ Green Check: Fully implemented and tested with BDD pytest

- 🟡 Yellow Check: Implemented but not yet tested with BDD pytest

- ❌ Red Cross: Not implemented

Overview

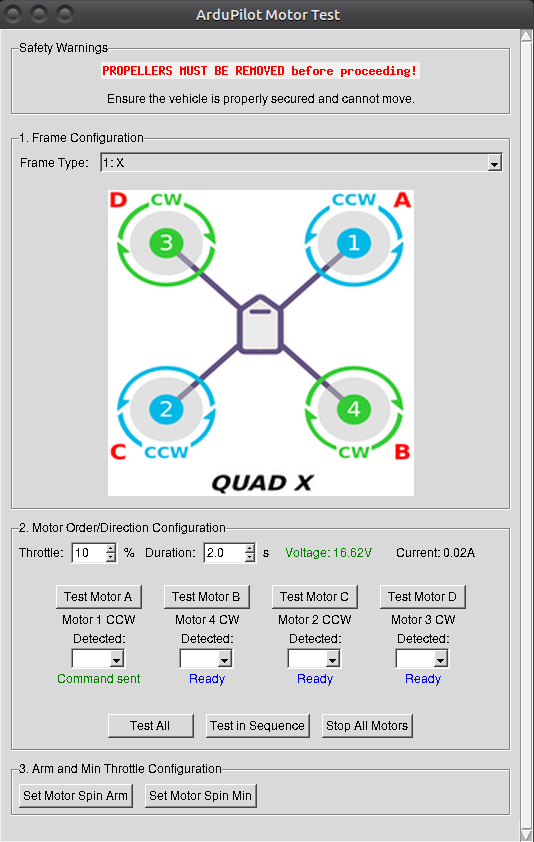

The Motor Test sub-application provides a graphical interface for testing individual motors on ArduPilot vehicles, similar to Mission Planner’s motor test functionality. It allows users to test motor functionality, verify motor order and direction, and configure motor parameters before flight.

Requirements Analysis

Functional Requirements

- Frame Configuration Interface

- ✅ FRAME_TYPE dropdown populated from parameter documentation metadata

- ✅ Immediate parameter application to flight controller on selection with progress feedback

- ✅ Progress windows showing flight controller reset and reconnection status

- ✅ Dynamic motor count calculation based on frame configuration

- ✅ Motor diagram display showing the currently selected frame configuration

- ✅ PNG motor diagrams loaded from local images directory (converted from ArduPilot documentation SVG files)

- The original diagrams are the

.svgfiles in thehttps://ardupilot.org/copter/_images/directory, converted to PNG for better compatibility

- The original diagrams are the

- Motor Parameter Configuration

- ✅ “Set Motor Spin Arm” button with parameter dialog for MOT_SPIN_ARM

- ✅ “Set Motor Spin Min” button with parameter dialog for MOT_SPIN_MIN

- ✅ Immediate parameter save and upload to flight controller

- ✅ Current value display and validation

- Motor Testing Interface

- ✅ Display N motor test buttons based on detected/configured frame

- ✅ Label buttons with “Test Motor” prefix followed by letters (A, B, C, D…) following ArduPilot conventions

- ✅ Expected direction labels (CW/CCW) for each motor position

- ✅ Detected order dropdown comboboxes for user feedback

- ✅ Status labels showing real-time feedback (“Ready”, “Command sent”, “Stop sent”, “Safety Check Failed”, “Invalid Parameters”, “Test Failed”, “Error”) with color coding

- ✅ Configurable test duration (default: 2 seconds)

- ✅ Real-time BATT1 voltage and current display with color-coded status

- ✅ “Test All” button for simultaneous motor testing

- ✅ “Test in Sequence” button for automated sequential testing

- ✅ “Stop All Motors” emergency stop button

- Battery Status Display

- ✅ Current BATT1 voltage and current readings (only when BATT_MONITOR != 0)

- ✅ When BATT_MONITOR == 0: Display “N/A”

- ✅ Color-coded voltage display based on BATT_ARM_VOLT and MOT_BAT_VOLT_MAX thresholds:

- Green: Voltage within BATT_ARM_VOLT to MOT_BAT_VOLT_MAX range (safe for motor testing)

- Red: Voltage outside the safe range (unsafe for motor testing)

- ✅ Safety popup when motor testing attempted with voltage outside safe range

- ✅ Real-time updates during motor testing operations

- Safety Controls

- ✅ Prominent red “Stop all motors” emergency button

- ✅ “Test in Sequence” button for automated testing

- ✅ Safety warnings and operational guidelines at top

- ✅ Parameter validation before motor testing

- ✅ Automatic motor timeout for safety

- Order Detection and Validation

- ✅ User-selectable “Detected” comboboxes for each motor

- 🟡 Comparison between expected and detected motor order

- ✅ Visual feedback for correct/incorrect motor placement

- 🟡 Guidance for correcting wiring issues

Additional Implemented Features (Beyond Original Requirements)

Enhanced User Experience

- ✅ Status column for real-time visual feedback during motor testing

- ✅ First-time safety confirmation popup

- ✅ Keyboard shortcuts for critical functions:

- Escape: Emergency stop all motors

- Ctrl+A: Test all motors simultaneously

- Ctrl+Q: Test motors in sequence

- ✅ Settings persistence for test duration and throttle percentage

- ✅ Enhanced error handling and user feedback messages

- ✅ PNG diagram display with improved compatibility (no external tksvg dependency required)

Advanced Safety Features

- ✅ Multiple safety confirmation layers

- ✅ Comprehensive parameter validation with bounds checking

- ✅ Motor direction display (CW/CCW) for each motor position

- ✅ Battery safety threshold validation with visual indicators

Non-Functional Requirements

- Safety

- ✅ Multiple safety warnings prominently displayed

- ✅ Clear indication of active motor testing

- ✅ Emergency stop functionality always accessible

- ✅ Safe parameter defaults and validation

- Usability

- ✅ Intuitive frame-based layout with logical workflow progression

- ✅ Clear visual feedback for active operations

- ✅ Immediate parameter application with confirmation

- ✅ Responsive UI with real-time feedback

- ✅ Keyboard shortcuts for critical functions

- ✅ Scrollable interface for frames with many motors

- Reliability

- ✅ Active flight controller connection required for all motor testing operations

- ✅ Robust error handling for communication failures

- ✅ Parameter validation and bounds checking

- ✅ Graceful degradation when features unavailable

- ✅ Comprehensive logging for debugging

- Performance

- ✅ Responsive UI updates during motor testing

- ✅ Efficient parameter reading/writing

- ✅ Minimal latency for emergency stop operations

- ✅ Low resource usage

System Design

Architecture Pattern

The motor test sub-application follows the Model-View separation pattern established in the project:

┌─────────────────┐ ┌──────────────────────┐

│ GUI Layer │ │ Data Model Layer │

│ │ │ │

│ frontend_tkinter│◄──►│ data_model_motor │

│ _motor_test.py │ │ _test.py │

│ │ │ │

│ - UI Layout │ │ - Business Logic │

│ - Event Handling│ │ - Parameter Mgmt │

│ - User Feedback │ │ - Frame Detection │

└─────────────────┘ └──────────────────────┘

│

▼

┌───────────────────────────────────────┐

│ Backend Layer │

│ │

│ ┌─────────────────────────────────────┤

│ │ backend_flightcontroller.py │

│ │ - Motor test commands (individual, │

│ │ all, sequence, emergency stop) │

│ │ - Battery monitoring & safety │

│ │ │ - Frame detection & motor count │

│ │ - MAVLink communication │

│ │ - Parameter read/write │

│ └─────────────────────────────────────┤

│ ┌─────────────────────────────────────┤

│ │ backend_filesystem.py │

│ │ - Safety validation logic │

│ │ - Frame configuration support │

│ │ - Parameter documentation metadata │

│ └─────────────────────────────────────┤

│ ┌─────────────────────────────────────┤

│ │ backend_filesystem_program_settings.py │

│ │ - Motor diagram PNG file access │

│ │ - Settings persistence (test duration)│

│ │ - Application configuration │

│ └─────────────────────────────────────┤

└───────────────────────────────────────┘

Component Responsibilities

Data Model Layer (data_model_motor_test.py)

Primary Responsibilities:

- Frame type detection and motor count calculation

- Motor label generation (numbers and letters)

- JSON-driven motor direction retrieval from AP_Motors_test.json with schema validation

- Parameter reading and writing (MOT_SPIN_ARM, MOT_SPIN_MIN)

- Battery status monitoring (BATT1 voltage and current when BATT_MONITOR != 0)

- Voltage threshold validation (BATT_ARM_VOLT and MOT_BAT_VOLT_MAX thresholds)

- Business logic validation

- Backend coordination and abstraction

Motor Order and Direction Logic Architecture

The motor test sub-application implements a robust JSON-driven architecture for motor test order and direction determination:

JSON Data Sources:

AP_Motors_test.json- Authoritative motor layout data from ArduPilot projectAP_Motors_test_schema.json- JSON schema for data structure validation

Key Features:

- ✅ Schema Validation: All JSON data validated against schema on load

- ✅ Frame-specific Lookup: Motor test order and directions retrieved based on FRAME_CLASS and FRAME_TYPE

- ✅ Motor Number Ordering: Directions sorted by motor number for consistent mapping

- ✅ Error Logging: Comprehensive logging for debugging and troubleshooting

Data Flow:

- JSON data loaded during model initialization with schema validation

- Motor test order and directions retrieved by matching current frame configuration

- Results sorted by motor number and adapted to expected motor count

- Error if frame not found or data invalid

Key Methods:

def __init__(self, flight_controller: FlightController, filesystem: LocalFilesystem, settings: ProgramSettings) -> None

def get_motor_count(self) -> int

def get_motor_labels(self) -> list[str]

def get_motor_numbers(self) -> list[int]

def get_motor_directions(self) -> list[str] # ✅ Returns CW/CCW direction labels from AP_Motors_test.json

def get_battery_status(self) -> Optional[tuple[float, float]] # voltage, current or None if BATT_MONITOR == 0

def get_voltage_status(self) -> str # "safe", "critical" "unavailable" or "disabled"

def is_battery_monitoring_enabled(self) -> bool # True if BATT_MONITOR != 0

def is_motor_test_safe(self) -> tuple[bool, str] # (is_safe, reason)

def set_parameter(self, param_name: str, value: float) -> tuple[bool, str] # (success, error_message)

def get_parameter(self, param_name: str) -> Optional[float]

def test_motor(self, test_sequence_nr: int, motor_letters: str, motor_output_nr: int, throttle_percent: int, timeout_seconds: int) -> tuple[bool, str]

def test_all_motors(self, nr_of_motors: int, throttle_percent: int, timeout_seconds: int) -> tuple[bool, str]

def test_motors_in_sequence(self, start_motor: int, motor_count: int, throttle_percent: int, timeout_seconds: int) -> tuple[bool, str]

def stop_all_motors(self) -> tuple[bool, str]

def get_motor_diagram_path(self) -> tuple[str, str] # Returns (filepath, description)

def motor_diagram_exists(self) -> bool

def get_test_duration(self) -> float

def set_test_duration(self, duration: float) -> bool

def get_test_throttle_pct(self) -> int

def set_test_throttle_pct(self, throttle: int) -> bool

def update_frame_configuration(self, frame_class: int, frame_type: int) -> tuple[bool, str]

def get_frame_options(self) -> dict[str, dict[int, str]]

def refresh_connection_status(self) -> bool

def get_voltage_thresholds(self) -> tuple[float, float] # Returns (BATT_ARM_VOLT, MOT_BAT_VOLT_MAX)

def refresh_from_flight_controller(self) -> bool # ✅ Refresh frame configuration from FC

def _load_motor_data(self) -> None # ✅ Load motor configuration from AP_Motors_test.json with schema validation

Data Attributes:

flight_controller: Backend flight controller interfacefilesystem: Backend filesystem interfacesettings: Backend program settings interface_frame_class: Detected vehicle frame class_frame_type: Detected vehicle frame type_motor_count: Number of motors for current frame_motor_data_loader: FilesystemJSONWithSchema instance for loading AP_Motors_test.json_motor_data: Loaded motor configuration data from JSON with schema validation

Backend Layer Distribution

The motor test sub-application backend logic is distributed across three specialized backend modules:

backend_flightcontroller.py - Flight Controller Communication

Responsibilities:

- Direct MAVLink communication with flight controller

- Motor testing command execution

- Real-time battery monitoring and telemetry with timestamp tracking (

_last_battery_message_time,_last_battery_status) - Parameter read/write operations

- Flight controller status monitoring

Key Motor Test Methods:

def test_motor(self, test_sequence_nr: int, motor_letters: str, motor_output_nr: int, throttle_percent: int, timeout_seconds: int) -> tuple[bool, str]

def test_all_motors(self, nr_of_motors: int, throttle_percent: int, timeout_seconds: int) -> tuple[bool, str]

def test_motors_in_sequence(self, start_motor: int, motor_count: int, throttle_percent: int, timeout_seconds: int) -> tuple[bool, str]

def stop_all_motors(self) -> tuple[bool, str]

def get_battery_status(self) -> tuple[Union[tuple[float, float], None], str]

def get_voltage_thresholds(self) -> tuple[float, float]

def is_battery_monitoring_enabled(self) -> bool

def get_frame_info(self) -> tuple[int, int]

def get_motor_count_from_frame(self) -> int

def fetch_param(self, param_name: str, timeout: int = 5) -> Optional[float]

Motor Test Implementation:

The motor test functionality uses MAVLink parameter handling:

- Individual Motor Testing: Uses

MAV_CMD_DO_MOTOR_TESTwithparam1=test_sequence_nr + 1,param5=0for single motor tests - Simultaneous Motor Testing: Rapidly sends individual

MAV_CMD_DO_MOTOR_TESTcommands for each motor to achieve simultaneous effect - Sequential Motor Testing: Uses

MAV_CMD_DO_MOTOR_TESTwithparam1=start_motor,param5=motor_countfor sequence testing - Parameter Fetching:

fetch_param()method for reliable parameter retrieval with timeout handling - Logging: Motor test commands log test sequence letters, output numbers, and detailed execution information

backend_filesystem.py - Safety & Parameter Support

Responsibilities:

- Motor testing safety validation logic

- Parameter default values and bounds checking

- Frame configuration from parameter metadata

- Parameter documentation access

backend_filesystem_program_settings.py - Diagrams & Settings

Responsibilities:

- Motor diagram PNG file access and validation

- User settings persistence with nested structure:

motor_test.durationandmotor_test.throttle_pct - Application configuration management

Key Motor Test Methods:

@staticmethod

def motor_diagram_filepath(frame_class: int, frame_type: int) -> tuple[str, str]

@staticmethod

def motor_diagram_exists(frame_class: int, frame_type: int) -> bool

backend_filesystem_json_with_schema.py - Motor Frames & rotation order and direction

Responsibilities:

- loading and validating AP_Motors_test.json

GUI Layer (frontend_tkinter_motor_test.py)

Primary Responsibilities:

- User interface layout and visual design

- Event handling and user interactions

- Real-time feedback and status updates

- Safety confirmations and warnings

- Integration with application window management

Key UI Components:

- Information and safety warnings at the top

- Frame configuration section with FRAME_TYPE combobox

- Arm and min throttle configuration with parameter buttons

- Motor order/direction configuration with test buttons and direction detection

- Real-time battery status display with color-coded voltage indication

- Prominent red emergency stop button and test sequence controls

- Status column for real-time motor testing feedback (NEW)

- Keyboard shortcuts for critical operations (NEW)

Enhanced Features:

- ✅ PNG diagram rendering with improved compatibility and reliability

- ✅ First-time safety confirmation popups

- ✅ Real-time status updates during motor testing

- ✅ Spinbox value management - Automatic initialization from data model and proper change handling

- ✅ Input validation and recovery - Invalid inputs gracefully handled with model fallback

- ✅ Keyboard shortcuts:

- Escape: Emergency stop all motors

- Ctrl+A: Test all motors simultaneously

- Ctrl+Q: Test motors in sequence

- ✅ Settings persistence for user preferences

- ✅ Enhanced error handling and logging

- ✅ Comprehensive test coverage - 34 BDD pytest tests ensuring reliability

Layout Structure:

┌─────────────────────────────────────────────────────────────────────┐

│ Information & Safety Warnings │

│ • PROPELLERS MUST BE REMOVED before proceeding! │

│ • Ensure the vehicle is properly secured and cannot move. │

├─────────────────────────────────────────────────────────────────────┤

│ 1. Frame configuration │

│ Frame Type: [FRAME_TYPE ▼] │

│ │

│ Frame Type PNG diagram │

│ │

├─────────────────────────────────────────────────────────────────────┤

│ 2. Motor order/direction configuration │

│ Throttle: [____] % Duration: [____] seconds Battery: 12.4V/2.1A │

│ │

│ [Test Motor A] Motor 1 CW [Detected: ▼] [Ready] │

│ [Test Motor B] Motor 2 CCW [Detected: ▼] [Ready] │

│ [Test Motor C] Motor 3 CCW [Detected: ▼] [Ready] │

│ [Test Motor D] Motor 4 CW [Detected: ▼] [Ready] │

│ ... │

│ │

│ [Test All] [Test in Sequence] [🛑 STOP ALL MOTORS] │

├─────────────────────────────────────────────────────────────────────┤

│ 3. Arm and min throttle configuration │

│ [Set Motor Spin Arm] [Set Motor Spin Min] │

└─────────────────────────────────────────────────────────────────────┘

Data Flow

User Workflow Sequence

- Safety Setup

- User reads safety warnings and ensures propellers are removed

- User secures vehicle to prevent movement during tests

- Frame Configuration

- User selects appropriate FRAME_TYPE from dropdown (populated from parameter documentation)

- Parameters are immediately applied to flight controller on selection

- Motor Testing and Order Detection

- User monitors real-time battery voltage and current display (if BATT_MONITOR != 0)

- User sets throttle % (default: 1%)

- User sets test duration (default: 2 seconds)

- User tests individual motors using labeled buttons (Test Motor A, B, C, etc.)

- User observes actual motor spinning and records in “Detected” comboboxes

- User can test all motors simultaneously or in sequence

- Real-time status feedback shows “Ready”, “Command sent”, or error messages for each motor

- Motor Parameter Configuration

- User clicks “Set Motor Spin Arm” to configure MOT_SPIN_ARM parameter

- User clicks “Set Motor Spin Min” to configure MOT_SPIN_MIN parameter

- Each button opens parameter dialog and saves/uploads value immediately

- System provides color-coded voltage feedback (green=safe, red=outside safe range)

- Safety popup appears when attempting motor test with voltage outside BATT_ARM_VOLT to MOT_BAT_VOLT_MAX range

- User can run “Test in Sequence” to automatically test all motors

- Emergency stop button available at all times during testing

- Order Validation

- System compares expected vs detected motor order

- User corrects any wiring issues based on feedback

- System provides guidance on proper motor/ESC connections

Motor Testing Workflow

- Initialization: GUI requests motor count and labels from data model

- Frame Detection: Data model reads FRAME_CLASS/FRAME_TYPE parameters

- Battery Monitoring: Data model reads BATT1 voltage/current and BATT_ARM_VOLT/MOT_BAT_VOLT_MAX thresholds (if BATT_MONITOR != 0)

- UI Setup: Dynamic button creation based on detected frame configuration

- Battery Validation: System checks voltage status before allowing motor tests

- User Action: User clicks motor test button

- Safety Validation: Data model validates parameters, battery status (if enabled), and safety conditions

- Execution: Motor command sent to flight controller via backend

- Feedback: UI updates to show active motor testing status and battery monitoring

- Completion: Automatic timeout or user stop action

Battery Safety Validation Workflow

- Motor Test Request: User clicks any motor test button

- Battery Monitor Check: Data model checks if BATT_MONITOR != 0

- Voltage Range Check: If battery monitoring enabled, validate voltage is within BATT_ARM_VOLT to MOT_BAT_VOLT_MAX range

- Safety Popup: If voltage outside safe range, display popup: “Battery voltage outside safe range. Please connect battery and/or ensure battery is in charged state.”

- User Action: User can choose to:

- Cancel motor test and address battery issue

- Override and proceed (with additional warning)

- Test Execution: Motor test proceeds only if voltage is safe or user explicitly overrides

Parameter Configuration Workflow

- Frame Selection: User selects FRAME_TYPE from dropdowns

- Immediate Application: Parameters uploaded to flight controller immediately

- Parameter Button: User clicks “Set Motor Spin Arm/Min” button

- Current Value: Data model reads current parameter value

- User Input: GUI presents input dialog with current value

- Validation: Data model validates new parameter value

- Update: Parameter uploaded to flight controller

- Confirmation: UI confirms successful parameter update

Testing Strategy

Current Test Coverage Status

Data Model Tests (tests/test_data_model_motor_test.py) - ✅ IMPLEMENTED

Status: 81 comprehensive BDD pytest tests implemented covering all functionality with 100% code coverage

Test Coverage Areas:

- ✅ Frame detection logic with various FRAME_CLASS/FRAME_TYPE combinations

- ✅ Motor count calculation for all supported frame types

- ✅ Motor label generation (number/letter mapping)

- ✅ Parameter validation and bounds checking

- ✅ Error handling for communication failures

- ✅ Motor testing command generation

- ✅ Battery monitoring and safety validation

- ✅ Settings persistence and configuration management

- ✅ Exception handling and edge cases

GUI Tests (tests/test_frontend_tkinter_motor_test.py) - ✅ IMPLEMENTED

Status: 34 comprehensive BDD pytest tests implemented covering frontend functionality with high test coverage

Test Coverage Areas:

- ✅ UI component creation and layout validation

- ✅ Button generation based on motor count changes

- ✅ Event handling for all interactive elements

- ✅ Safety confirmation dialogs and user interactions

- ✅ Parameter input validation and error handling

- ✅ Integration with data model layer via dependency injection

- ✅ Keyboard shortcut functionality verification

- ✅ PNG diagram rendering and error handling

- ✅ Spinbox initialization and change handling

- ✅ Frame type selection and immediate parameter application

- ✅ Battery status monitoring and display updates

- ✅ Motor status visual feedback during testing

- ✅ Emergency stop functionality and safety mechanisms

Integration Testing

End-to-End Scenarios

- Complete motor testing workflow from GUI to flight controller

- Parameter configuration and validation

- Emergency stop functionality

- Multi-frame type support validation

Mock Testing Strategy

- Flight controller communication mocking

- Parameter read/write simulation

- Frame detection with various configurations

- Error condition simulation

- Safety mechanism testing

Test Fixtures and Patterns

Following project pytest guidelines with BDD structure:

@pytest.fixture

def mock_flight_controller() -> MagicMock:

"""Fixture providing mocked flight controller with realistic responses."""

@pytest.fixture

def motor_test_data_model(mock_flight_controller) -> MotorTestDataModel:

"""Fixture providing configured motor test data model with dependency injection support."""

@pytest.fixture

def motor_test_view_setup() -> tuple[MagicMock, ...]:

"""Fixture providing complete mock setup for testing MotorTestView without full window creation."""

@pytest.fixture

def motor_test_window(motor_test_data_model) -> MotorTestWindow:

"""Fixture providing configured motor test GUI window for integration testing."""

def test_user_can_test_individual_motor(self, motor_test_view_setup) -> None:

"""

User can test individual motors safely.

GIVEN: A configured motor test view with mock dependencies

WHEN: User clicks a motor test button

THEN: The corresponding motor should activate with proper validation and feedback

"""

def test_spinbox_values_initialize_from_data_model(self, motor_test_view_setup) -> None:

"""

Spinbox values are properly initialized from the data model.

GIVEN: A motor test view with configured data model

WHEN: The view is updated

THEN: Spinbox values should reflect the current model values

"""

def test_spinbox_changes_update_data_model(self, motor_test_view_setup) -> None:

"""

Spinbox changes properly update the data model.

GIVEN: A motor test view with Spinbox widgets

WHEN: User changes Spinbox values

THEN: The data model should be updated with the new values

"""

Implementation Status Summary

✅ COMPLETED FEATURES

Core Functionality:

- ✅ Complete data model with 30+ methods (100% test coverage with 81 BDD pytest tests)

- ✅ Full Tkinter GUI implementation with all required components (34 BDD pytest tests with comprehensive coverage)

- ✅ Enhanced Model-View separation with dependency injection for improved testability

- ✅ Real backend integration (FlightController, LocalFilesystem, ProgramSettings)

- ✅ Frame configuration with parameter metadata integration

- ✅ Motor testing (individual, all, sequence, emergency stop)

- ✅ Battery monitoring with safety validation

- ✅ Parameter configuration (MOT_SPIN_ARM, MOT_SPIN_MIN)

- ✅ PNG diagram rendering with improved compatibility

- ✅ JSON-driven motor direction logic with schema validation (AP_Motors_test.json)

- ✅ Motor rotation direction display (CW/CCW) from authoritative ArduPilot data

- ✅ Motor count mismatch handling with extension/truncation for various frame configurations

- ✅ Spinbox value synchronization - proper initialization from data model and change handling

Enhanced Features:

- ✅ Status column for real-time feedback

- ✅ Keyboard shortcuts for critical functions

- ✅ First-time safety confirmation

- ✅ Settings persistence with Spinbox initialization from data model

- ✅ Enhanced error handling and logging

- ✅ Motor direction display (CW/CCW)

- ✅ FilesystemJSONWithSchema integration for robust JSON loading and validation

🟡 PARTIAL FEATURES (Implemented but not fully tested)

- 🟡 Motor order comparison and validation logic (framework present)

- 🟡 Wiring issue guidance (basic framework implemented)

❌ MISSING FEATURES

- ❌ End-to-end integration tests with real flight controller hardware

- ❌ Advanced motor order validation algorithms with automatic correction suggestions

Dependencies and Requirements

Backend Dependencies

- ✅

backend_flightcontroller.py- All required motor test methods verified present - ✅

backend_filesystem.py- Enhanced withget_frame_options()method - ✅

backend_filesystem_program_settings.py- Settings persistence implemented - ✅

backend_filesystem_json_with_schema.py- JSON loading with schema validation for motor data - ✅

annotate_params.py- Parameter metadata parsing support

File Dependencies

- ✅ Motor diagram PNG files in

ardupilot_methodic_configurator/images/motor_diagrams_png/directory - ✅ Parameter documentation metadata files (

.pdef.xml) - ✅ Frame configuration JSON schemas

- ✅ AP_Motors_test.json - Motor layout configuration data with motor positions, rotations, and test order

- ✅ AP_Motors_test_schema.json - JSON schema for validating motor configuration data structure

Implementation Guidelines

Code Style Requirements

- Type Hints: All functions must include complete type annotations

- Documentation: Comprehensive docstrings following project standards

- Error Handling: Graceful error handling with user feedback

- Logging: Appropriate logging for debugging and audit trail

- Internationalization: All user-facing strings wrapped with

_()

Safety Implementation

- Parameter Validation: ✅ All parameters validated before sending to FC

- Battery Monitoring: ✅ Real-time battery voltage monitoring with BATT_ARM_VOLT/MOT_BAT_VOLT_MAX threshold validation (when BATT_MONITOR != 0)

- Voltage Safety: ✅ Safety popup when attempting motor test with voltage outside safe range, prompting user to connect battery and/or ensure charged state

- Timeout Mechanisms: ✅ Automatic motor stop after configured timeout

- Emergency Stop: ✅ Always accessible stop functionality with keyboard shortcut (Escape)

- User Confirmation: ✅ Display a Safety confirmation popup the first time a Motor test button is pressed

- Visual Feedback: ✅ Clear indication of active motor testing (status column) and battery status (green/red voltage display)

- Multi-layer Safety: ✅ Multiple confirmation dialogs and safety checks throughout the workflow

Performance Considerations

- Lazy Loading: UI components created only when needed

- Efficient Updates: Minimal UI updates during motor testing

- Resource Management: Proper cleanup of timers and connections

- Responsive Design: Non-blocking operations for UI responsiveness

Integration Points

Main Application Integration

The motor test sub-application integrates with the main ArduPilot Methodic Configurator through:

- Menu Integration: Accessible from dedicated button

- Flight Controller Sharing: Uses existing FC connection

- Parameter Context: Reads current vehicle configuration (LocalFilesystem)

- Logging Integration: Uses application logging framework

- Settings Persistence: Saves user settings (test duration in ProgramSettings)

Backend Architecture Integration

The motor test sub-application leverages the existing backend infrastructure without requiring additional backend modules:

Flight Controller Backend Integration (backend_flightcontroller.py)

- Existing Infrastructure: Utilizes the established MAVLink connection and parameter system

- Motor Commands: All motor testing functionality is already implemented with proper error handling

- Battery Monitoring: Real-time telemetry integration with safety threshold validation

- Frame Detection: Automatic vehicle configuration detection from flight controller parameters

Filesystem Backend Integration (backend_filesystem.py)

- Safety Framework: Leverages existing parameter validation and safety check infrastructure

- Configuration Management: Uses established parameter default and metadata systems

- Documentation Access: Integrates with existing parameter documentation framework

Program Settings Integration (backend_filesystem_program_settings.py)

- Motor Diagrams: Comprehensive PNG diagram support for all ArduPilot frame types

- Settings Persistence: Consistent user preference storage using established patterns

- Resource Management: Proper handling of application resources and file paths

This architecture demonstrates the project’s modular design - new sub-applications can be implemented by primarily creating frontend and data model layers while leveraging the robust, tested backend infrastructure that already exists.

ArduPilot Integration

Communication with ArduPilot flight controller via:

- MAVLink Protocol: Standard parameter and command protocols

- Parameter System: Read/write MOT_* parameters

- Motor Commands: Direct motor control via MAVLink

- Status Monitoring: Real-time status and safety monitoring

- Frame Detection: Automatic vehicle configuration detection

Security Considerations

Safety Measures

- Parameter Bounds: Strict validation of all motor parameters

Risk Mitigation

- Hardware Safety: Clear warnings about propeller removal

- Software Safety: Multiple layers of safety checks

- Communication Safety: Robust error handling for comm failures

- User Safety: Clear operational guidelines and warnings

This architecture provides a comprehensive foundation for implementing a safe, reliable, and user-friendly motor test sub-application that integrates seamlessly with the ArduPilot Methodic Configurator while maintaining the highest safety standards for motor testing operations.